The Kuhn GA 15131 rake, with a working width of 9.50 to 14.7 metres, currently holds the world record, established in Denmark in 2019, for raking output, where it was able to rake 188.9ha in only 8 hours.

The GA 15131 rake and its smaller GA 13131 brother have morphed into the 10231 series that feature numerous upgrades.

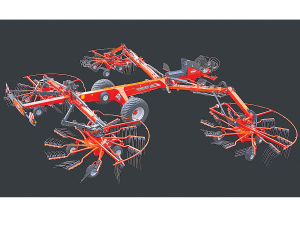

Recognisable by the GA 13231 and GA 15231 designations, the fourrotor, central delivery rakes offer working widths from 8.4m to 14.7m.

Major developments include new electronic architecture, which incorporates the new ISOBUS M500 module, the latter more powerful, with more capacity and offering more possibilities than the former model.

The ISOBUS terminal interface for the machine’s control has also been redesigned to more user-friendly, including generating graphic icons related to the various functions for use with the ISOBUS CCI A3 joystick.

Other upgrades include individual working width adjustment as standard, while the suspension of the front rotors is now carried out via hydraulic cylinders allowing a more precise adjustment.

Automatic ground pressure adjustment is possible depending on the working width. These two key features allow the user to easily adjust the machine to the working conditions, minimising dirt ingress and preserving the sward.

Other improvements include a new adjustment of the working height control, a new hydraulic block with new electronic management, alongside new sensors throughout for improving precision and system diagnosis.

All the features that have made the KUHN four-rotor rakes popular have been retained, including the exclusive 100% hydraulic drive system, that allows perfect adaptation of rotor speed to the forage type and yield, while minimising maintenance work.

The BOOST function improves windrow quality by increasing the speed of the front rotors by 20% compared to the rear rotors to build a homogeneous and airy windrow. The individual rotor lifting allows operators to avoid obstacles and adapt work to the changing shape of the paddocks.