With slurry and dairy effluent being recognised as an asset by most farmers, it makes sense to have it applied in a way that makes the most of the nutrients carried within.

Indeed, by considering it a fertiliser, it should be applied as any other dressing.

German effluent specialists Vogelsang has provided equipment for many years, either attached to a tanker or via an umbilical system, so took the opportunity at the recent LAMMA Show in the UK to display its new 24m BacPac Umbilical ground-level application boom with section control and variable rate flow meter.

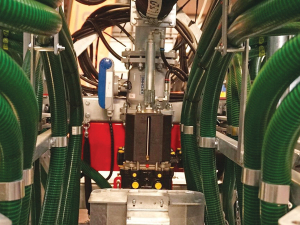

At the heart of the BacPac unit is a Krohne flow meter, while Section Control is achieved by the inflation of small balloons in the feed pipes to the part of the boom that needs to be switched off, a valve system said to be unique to the company.

The system is ISOBUS compatible so may be used with prescription mapping or, in the future, a Near Infra Red (NIR) sensor such as John Deere's harvest lab.

The company was also showing its DoubleFlow shoe which splits the flow of slurry, delivering two lines at 12.5cm apart, rather than a larger, more typical layout at 25cm spacing. The company claims this will help achieve a more even distribution of slurry, as well as increasing the surface area in contact with the soil and air, thereby accelerating absorption by the soil and faster aerobic breakdown of the product.

|

|---|

|

The DoubleFlow shoe splits the flow of slurry, delivering two lines at 12.5cm apart.

|

Vogelsang notes that the greatest number of complaints about ground spreading is that the process can leave unabsorbed slurry on the surface that can lead to contamination of the cut sward and in severe cases, kill off the grass. By spreading material thinner, this problem is largely avoided.

The double runner system will be available for the UniSpread and BlackBird trailing shoe linkage series from May 2024 and can also be retrofitted to older machines.