While Yardmaster shore-mounted stirrers have been around for a few years, health & safety compliance, innovation and ease of maintenance has been driving this product to a market leading position.

The point around health & safety is reasonably obvious when you conduct a risk assessment of a shore-mounted system compared to a stirrer mounted to on a floating frame/pontoon within the pond area. With the ability to swing the shore-mounted stirrer back over land, any maintenance can be safely carried out without going out over the pond area.

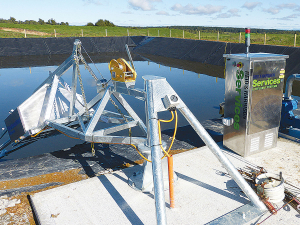

Regarding innovation, the latest model of Yardmaster shore-mounted stirrers has a rapid installation method, using a mounting plate that is inserted in the concrete base pad, onto which the stirrer can be quickly and safely located without the need for counterweights. Equipped with a winch system relative to the size of stirrer, to easily change the operating angle, they also feature multiple locating holes in the swivel plate, allowing adjustment on the horizontal plane to where you wish to aim the stirrer.

Recently introduced auto lube kits can also be installed, reducing need for manual maintenance.

With over 60 years of amassed knowledge and experience, Yardmaster has deliberately stuck to a format that has held true to them, by getting the motor out of the liquid if possible.

Having a shore-based motor and a pulley drive to the main shaft means that any expensive componentry is located on land. By contrast, submersible options, where motors are submerged in corrosive liquids, can see motor issues evolving into the need to replace the complete stirrer unit.

Looking at maintenance more closely, besides the ease of access, the general construction of the Yardmaster units means there is very little to go wrong.

Should the propeller hit a foreign object, the stirrer can be swung back to shore and the prop repaired or replaced. Drive belts will occasionally need adjustment as they wear and of course might need eventual replacement, all done easily, and importantly, over dry land.

With 7.5m and 9.9m machine lengths, alongside the options of 7.5kW and 11kW motors, the stirrer can be customised to suit any pond size, so Yardmaster would highly recommend you use a certified designer to calculate your pond size and use a certified dealer to match the stirrer needed to the pond size.