JCB is getting ready for the international debut of its super-efficient hydrogen combustion technology with a debut in North America.

JCB’s new hydrogen combustion engine, the company’s zero-carbon emissions solution for construction and agricultural equipment, will be showcased at the Conexpo 2023 show in Las Vegas in March, as part of the International Fluid Power Exposition (IFPE).

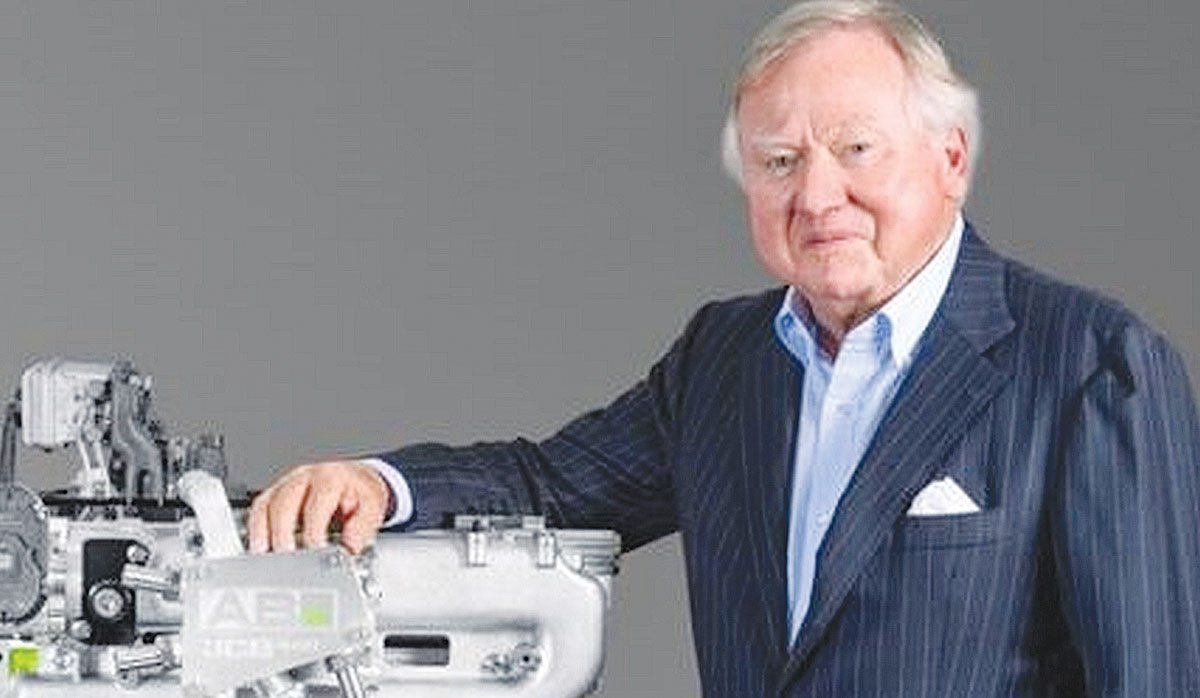

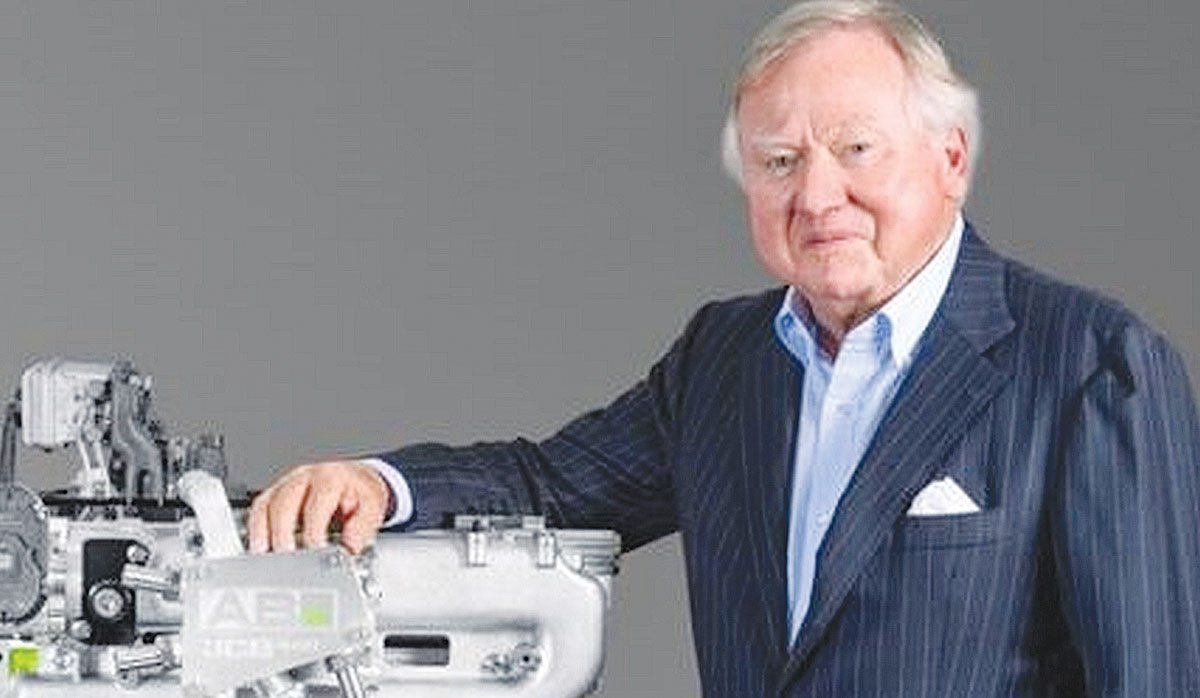

The project, driven by JCB chairman Lord Bamford, has seen the JCB engineering team make enormous strides in a relatively short time, to develop a hydrogen internal combustion engine that is already powering prototype versions of a company backhoe loader and a Loadall telescopic handler.

As the first construction equipment company to develop a fully working combustion engine fuelled by hydrogen, the company leads the way in environmental, social and governance (ESG) for the construction equipment sector, while also having been responsible for a series of industry innovations on its ‘Road to Zero’.

JCB developed the world’s first batteryelectric mini excavator and went on to focus on electric technology development to meet customers’ demands for zero-carbon products with its E-TECH range, said to be the largest electric line-up available in the construction industry.

JCB’s commitment to reducing emissions started almost 25 years ago and today its latest diesel engines have already delivered a 97% reduction in NOx emissions since 1999 and a 98% reduction in particulates. JCB’s diesel-powered machines also emit 50% less CO2 compared with those manufactured in 2010.

Other manufacturers are also committed to exploring alternative power sources, with French company Manitou, known for its telescopic handlers and fork trucks, appearing to favour an electrical drive train, with two initiatives being driven to this end.

The first centres around developing a hydrogen-powered telehandler prototype, initially targeted at the construction industry. Unlike JCB, the French company is pursuing hydrogen fuel cell technology, said to be a far more efficient method of releasing the energy than combustion.

|

|---|

|

JCB chairman Lord Anthony Bamford.

|

This method produces power directly from the fuel cell without the need for generators to convert mechanical energy to electricity, but they are expensive due to the need for a platinum catalyst within the cell. At this point platinum supplies are very limited so carry a high price.

Manitou is also researching the possibility of using batteries to power its electrically driven machines and has invested in a battery fabrication company.

EasyLi, based in Poitiers, Central France, is described as “a specialist in the design and production of mass produced and custom-built lithium-ion batteries”.

By purchasing 87% of the company, Manitou has acquired specific skills in the context of its energy transition strategy, alongside securing the ability to design and build its own batteries rather than relying on third party providers.