Fonterra’s exit from Australia ‘a major event’

Fonterra’s impending exit from the Australian dairy industry is a major event but the story doesn’t change too much for farmers.

We have all had to deal with milk quality issues onfarm at some stage in our farming careers — whether it be a freezing point grade or high bulk somatics on the first pick-up or perhaps an antibiotic scare during the season.

These three issues are some of many we are tested on and any one of them could result in demerits or a grade, thereby lowering our income.

We also need to be aware of regulation changes on feeding (FEI) and milk cooling. What we have always done is often not the way of the future. We need to understand and adapt.

The key point is that we are in the business of providinghigh-qualityy food to people around the world. If we cannot provide ahigh-qualityy product then our respective dairy companies cannot provide one either.

Reputation in food safety and quality is paramount when securing the best possible prices for our milk.

Below are some key short points on providing some of the highest milk quality standards in the world.

Note that some of the values below are specific to Fonterra as I am more familiar with their requirements. These values may be different depending on your milk processor.

Milk chilling

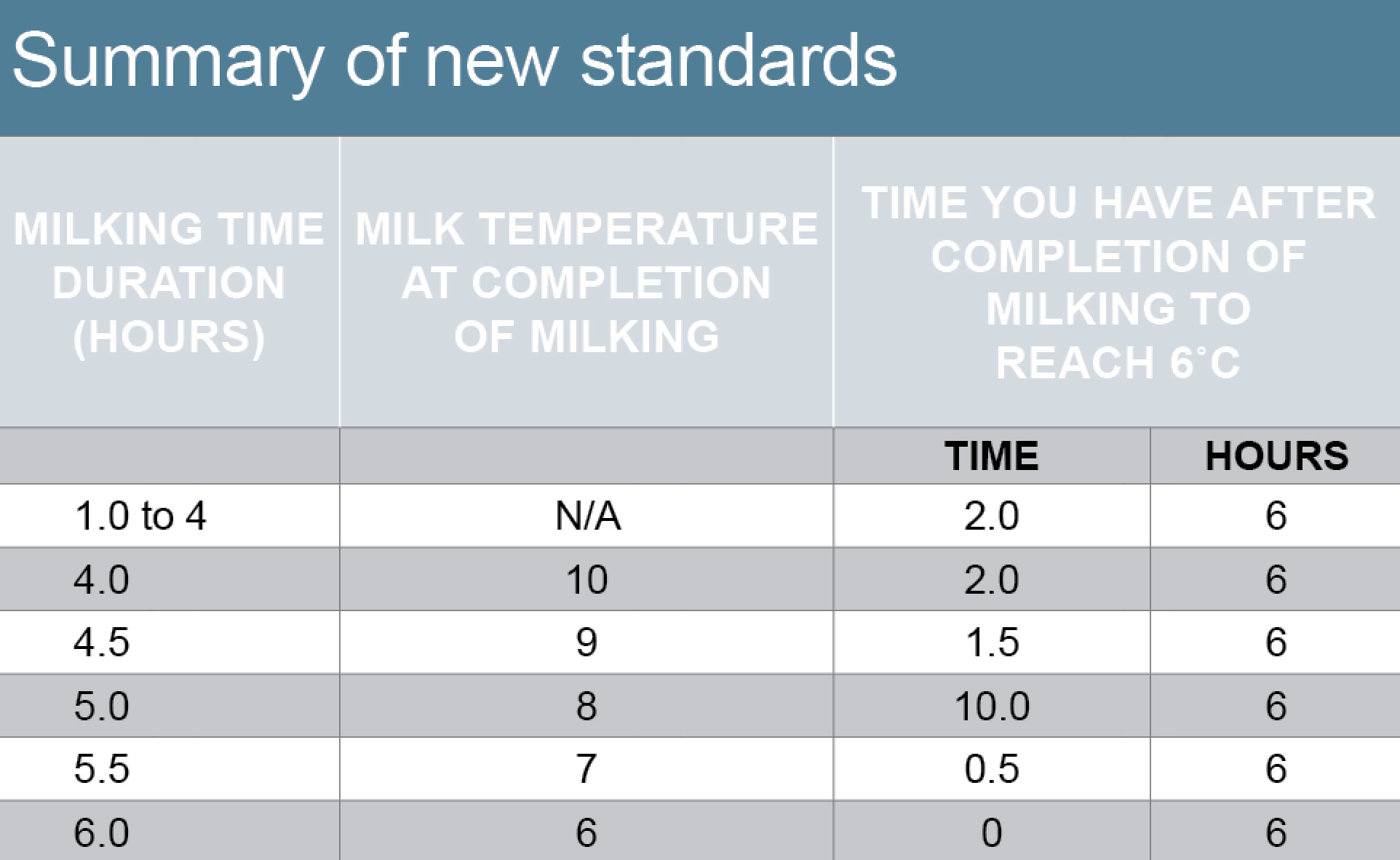

The new MPI requirements came into effect on June 1, 2018.

Under the new standards, milk must:

- Be cooled to 10C or below within four hours of the start of milking

- Be cooled to 6C or below either within six hours from the start of milking or two hours from the end of milking

- Not exceed 10C during subsequent milkings.

- A simple check of your system should identify the area you need to focus on to meet the new standards.

- Start with your water temperature into the plate cooler

- Temperature tabs can be sourced from your milk processor

- What is your plate size, what is the temperature of milk out of the cooler?

- Is your plate size sufficient?

- Is your chiller size sufficient?

- If so, water chilling may be your best option

- If not, a larger chiller may be your best option

- Is your power transformer large enough?

Research these options and discuss them with many providers who will be able to provide quotes. I have seen costs range from $5000 to $70,000 onfarm.

Some time spent researching information to obtain the correct advice and installation can be a high $/ hour rate saving to you. Most dairy companies have more information on this topic to aid your research. Use a trusted installer.

Milk quality

Most milk quality issues onfarm are management or people issues.

Most milk quality issues onfarm are management or people issues.

Plant issues do occur but often we identify issues too late then react once the grade is already incurred; whereas proactive management will avoid most issues.

Key points:

- Training – even if we think we know it all; revise at least annually

- Regularly inspect milking plants

- Use correct wash cycles every day

- Check and ensure wash cycles are working properly. Too often I hear “the purge wash was playing up and didn’t clean properly”; that is not the purge system’s fault; we can monitor these things at a glance on a daily basis

- Ensure all staff are familiar with plant systems

- Check milk sanitary traps (if applicable)

- Open pulsation line daily; are there milk deposits?

It is up to us to complete our plant checks and determine whether our cowshed is operating optimally.

Most dairy companies provide you an early warning system, and some of the tests take time to confirm; we cannot control that. What we can control is our monitoring via alerts, dockets and internet.

There is lots of information and prevention methods available from your dairy processor; spend some time training yourself and your staff. Take nothing for granted; “this has never happened to me before” will still incur penalty for the grade.

Fat Evaluation Index (FEI)

FEI has been a talking point in the last 12 months.

Our first reaction is generally scepticism followed by anger at a perhaps ‘nanny state’ and what a lack of PKE inputs at certain times of the year may have on our profitability, production and overall performance.

Once we square all of that away and focus on the outcome, we can then determine how FEI grading might affect our farm’s strategy.

FEI is not a PKE test, although PKE has a far greater impact on fatty acid profile than any other feed source. We have now had quite some time – if we are feeding high fatty acid feeds – to determine where our farm system sits on the grading profile.

A and B grades will not require any changes.

C and D grading will certainly require some planning and thought on future management.

Key points:

- Cow breed will affect FEI outcome. For any given input, Jerseys will have higher FEI reading than crossbreeds followed by Friesians

- FEI will be higher for any given input the lower the LWT is

- A higher proportion of fatty acid input as a percentage of total intake will increase FEI

- As milk volumes decrease FEI will increase eg 3kg PKE in late autumn will increase FEI higher than 3kg PKE in spring

- There are no other feeds that reverse the effect of PKE

I have seen large variations in grade outcome between farms: 3kg PKE to a Jersey herd equated to C grading; 4kg PKE to a high LWT Friesian herd equated to B grading.

Also a combination of feeds, e.g. 2kg PKE combined with 5kg of summer turnips will have an effect on FEI.

Monitor your graphs regularly. It is important to know how your farm may react. I understand the criteria for grading are due to be released very shortly. Ensure you are informed if your farm system might be affected.

All the topics above are manageable. We need to spend the time required to understand and adapt to those changes.

• This article first appeared in Getting the Basics Right 2018 issue

Fonterra’s impending exit from the Australian dairy industry is a major event but the story doesn’t change too much for farmers.

Expect greater collaboration between Massey University’s school of Agriculture and Environment and Ireland’s leading agriculture university, the University College of Dublin (UCD), in the future.

A partnership between Torere Macadamias Ltd and the Riddet Institute aims to unlock value from macadamia nuts while growing the next generation of Māori agribusiness researchers.

A new partnership between Dairy Women’s Network (DWN) and NZAgbiz aims to make evidence-based calf rearing practices accessible to all farm teams.

Despite some trying circumstances recently, the cherry season looks set to emerge on top of things.

Changed logos on shirts otherwise it will be business as usual when Fonterra’s consumer and related businesses are expected to change hands next month.

OPINION: Fonterra may be on the verge of selling its consumer business in New Zealand, but the co-operative is not…

OPINION: What does the birth rate in China have to do with stock trading? Just ask a2 Milk Company.