The opening of Bovonic’s new facility near Tauranga late last year will allow the company to commercialise the production of its mastitis detection technology, QuadSense, to meet farmer demand and support plans for international expansion.

The company will be keeping product assembly in-house, allowing it to uphold stringent quality control and achieve significant cost savings, so it can continue offering an affordable price point for farmers.

QuadSense was officially launched at National Fieldays in June last year. In just 6 months, more than 1,000 units have been installed on New Zealand dairy farms, delivering immediate benefits such as reduced bulk somatic cell counts, improved herd health, and time savings for farmers.

With this strong foundation at home, Bovonic is now preparing for a UK and Ireland market launch. The company has already established trial farms in Ireland and received positive feedback from international trade shows, validating QuadSense for overseas markets.

“Keeping our final assembly in-house has been a game-changer,” says Bovonic founder Liam Kampshof.

“It allows us to maintain absolute control over product quality, which has always been our top priority. And these are also the first premises we’ve had with windows – natural light makes a big difference after spending years tinkering away in dark sheds!”

Kampshof dreamed of becoming an inventor from the age of eight. Celebrating this milestone has been an opportunity for him to reflect on how far Bovonic has come since its inception in 2021.

“I started with a prototype made from a Bunnings pipe and a 3D-printed sensor,” he says.

“We tested the concept at Fieldays and had 150 farmers sign up, saying they’d buy something like this if it existed. That early validation gave us the confidence to move forward - and here we are, a few years later, with over 1,000 units installed.”

Farmer feedback has been integral to Bovonic’s success, shaping the development of the QuadSense system and its app.

“Initially, we didn’t plan on creating an app,” Kampshof admits. “But farmers told us they needed easier ways to track alerts and adjust thresholds, so we created a tool that makes recordkeeping seamless and improves usability.”

A $940,000 capital investment last year has supported QuadSense’s launch, product development, IP protection, and exploration of overseas markets. The company says the technology has transformed mastitis management, offering farmers peace of mind and tangible results.

“One farmer told us he found 15 staph cases in just one month using QuadSense,” says Kampshof. “That level of early detection not only saved his herd, but also reduced his stress and prevented the spread of harsh, contagious strains of mastitis.”

Bovonic’s next steps include setting up a New Zealand distribution network, validating Quad- Sense for rotary sheds, and continuing international trials ahead of its UK and Ireland launch.

To support this growth, immediate hires include a product development lead to drive innovation and a customer success representative to enhance farmer support.

“The best decision I’ve made was hiring people who are smarter than me,” says Kampshof. “It’s been a huge part of our growth, and I’m incredibly grateful to my team and investors for believing in our vision.”

Bovonic says it is committed to improving animal health, farm profitability, and environmental outcomes. It says QuadSense reduces the need for antibiotics, helps lower somatic cell counts, and aligns with the dairy industry’s emissions reduction goals.

“This milestone is just the beginning,” says Kampshof.

“Our vision is to make QuadSense as indispensable to dairy farmers as automatic cup removers. It’s about creating technology that’s simple, affordable, and truly valuable for farmers.”

|

|---|

|

Over 1,000 QuadSense units have been installed on New Zealand dairy farms.

|

Fast, Accurate

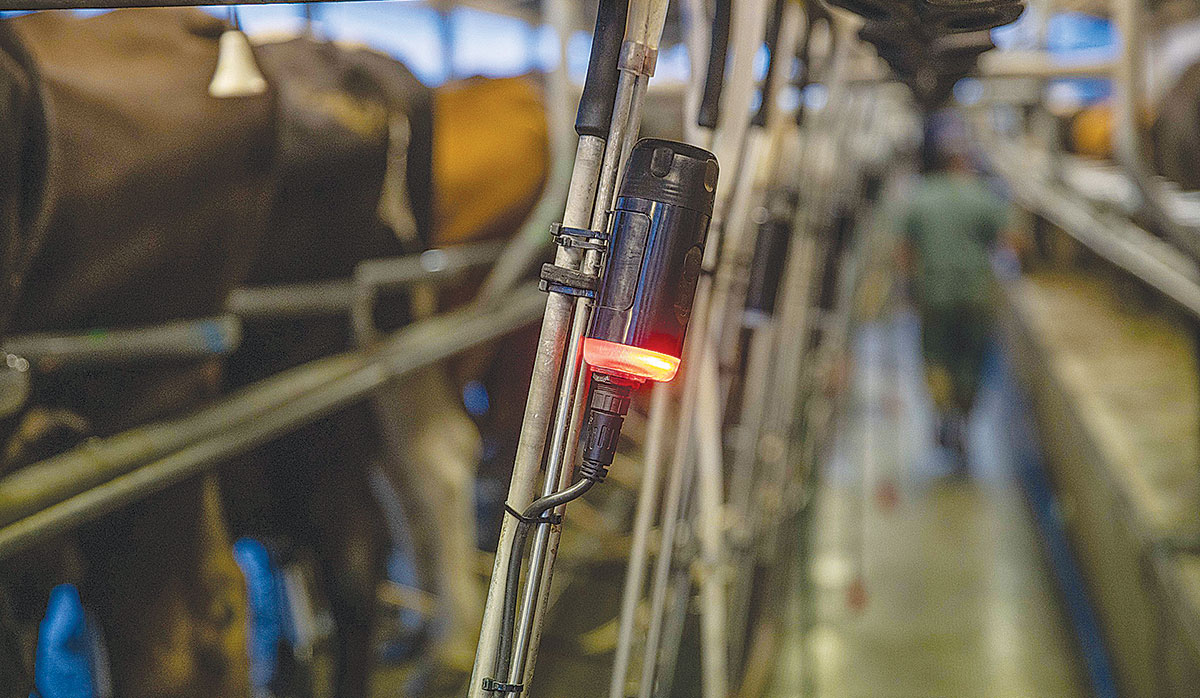

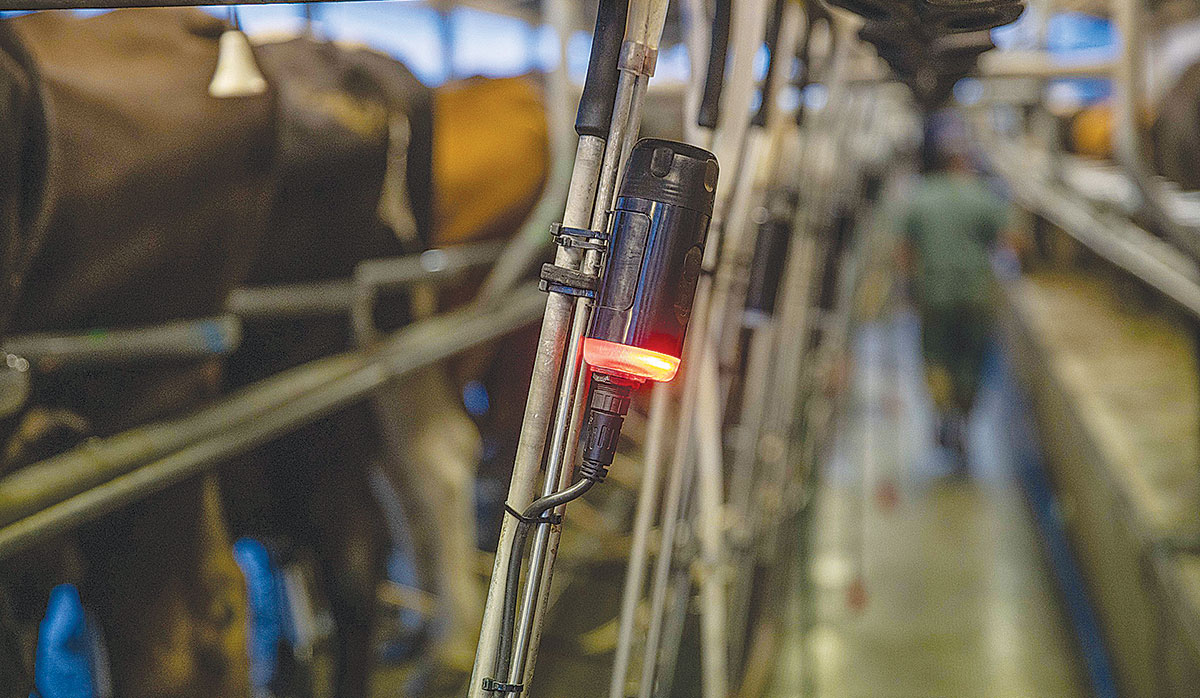

QuadSense is made up of four patented milk sensors that are inserted into the four liners of the milking cups. By measuring and comparing milk from each quarter of the udder, QuadSense can achieve greater accuracy than other in-line mastitis detectors.

QuadSense starts measuring milk as soon as the cups are on, then gives a result after just a minute.

It can be installed by farmers into any milking cup liner and gives a red-light alert when mastitis is present.

DairyNZ estimates the cost of mastitis across the New Zealand dairy industry is $180 million per year.