GEA launches AI-powered walkover teat sprayer

GEA says that its latest walkover teat sprayer is helping farmers save time and boost udder health.

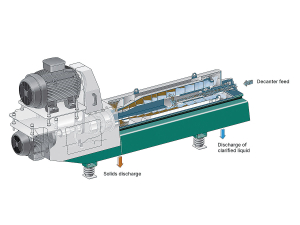

The manure decanter separates solids from liquids, creating nutrient-rich fertiliser and irrigation water.

The manure decanter separates solids from liquids, creating nutrient-rich fertiliser and irrigation water.

In a groundbreaking move for dairy farming in New Zealand, Craig Copland has become the first farmer in the country to use GEA’s Manure Decanter system, traditionally used in wastewater and wineries, to enhance environmental sustainability on his Canterbury farm.

Copland and his brother Wayne have successfully integrated GEA’s Manure Decanter system into their farming operations in Chertsey, Canterbury.

“This system has significantly improved pasture irrigation on the farm,” says Craig.

The dairy farm which has been in their family for over 140 years, includes dairy, Black Origin Wagyu beef, cropping, and an apple orchard. With 1500 cows milked through a 60-bail GEA rotary, the system five dairy farm houses 600 cows and 1000 Wagyu beef animals indoors, producing a large volume of effluent.

Before implementing the GEA Manure Decanter, Craig was using a GEA Screw Press separator but faced challenges with irrigation nozzle blockages and high levels of potassium and phosphate in his paddocks.

Daniel Geldenhuys, sales engineer and business development for GEA’s Separator & Flow Technologies, says the company is committed to providing innovative solutions that support sustainable farming practices.

“The GEA Manure Decanter, adapted for use on Craig’s farm, separates solids from liquids, creating nutrient-rich fertiliser and irrigation water. The clarified liquid is fed to a nearby irrigation pond and the solids are dropped underneath the decanter into a concrete bunker,” he says.

The GEA system has reduced irrigation nozzle blockages and allowed for more efficient use of natural fertilisers.

This is the first system of its type in New Zealand.

“Since installing the decanter, we have seen a dramatic increase in irrigation run time from blocking nozzles in less than 8 hours to now endless running times, along with improved pasture growth and reduced synthetic fertiliser use,” says Craig.

“The decanter system has saved time and money on the farm, the other option we looked at was a slurry truck system, which would have involved transporting 24 million litres of effluent in 30,000-litre loads.

“I can operate the system myself, whereas slurry trucks require a driver to transport and spread slurry over fields, and regular maintenance”, says Craig.

Recent weather events in the Bay of Plenty, Gisborne/Tairawhiti, and Canterbury have been declared a medium-scale adverse event.

DairyNZ's chief executive Campbell Parker says the 2024/25 dairy season reinforces the importance of the dairy sector to New Zealand.

A New Zealand agribusiness helping to turn a long-standing animal welfare and waste issue into a high-value protein stream has won the Australian dairy sector's top innovator award.

OPINION: A bumper season all around.

Dairy Women's Network (DWN) has announced that Taranaki dairy farmer Nicola Bryant will join its Trust Board as an Associate Trustee.

Rural Women New Zealand (RWNZ) says it welcomes the release of a new report into pay equity.

OPINION: A mate of yours truly reckons rural Manawatu families are the latest to suffer under what he calls the…

OPINION: If old Winston Peters thinks building trade relations with new nations, such as India, isn't a necessary investment in…