New telemetry solution

Part of the AGCO stable, Fendt, is introducing Fendt Connect – a new generation telemetry solution for Australian and New Zealand customers, said to offer improved productivity, efficiency, and profitability.

Machinery product and parts supplies for the Australasian markets are likely to come under pressure due to the second wave of Covid lockdowns currently happening in Europe.

Machinery product and parts supplies for the Australasian markets are likely to come under pressure due to the second wave of Covid lockdowns currently happening in Europe.

With a second wave of Covid-19 bringing Europe to a dramatic slowdown, as more severe lockdowns are imposed, reports suggest that product and parts supplies for the Australasian markets are likely to come under pressure.

It is likely to become a greater problem as we move into the second part of 2021. This is due to our growing season being the reverse of the Northern Hemisphere and falls at a time when there are annual factory summer shutdowns.

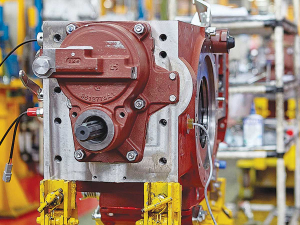

While production is continuing, with most manufacturers implementing lessons learned during “Lockdown 1”, the likelihood is that overall production levels will be difficult to maintain because externally-sourced key component supplies – such as hydraulic pumps, batteries and tyres – are said to be tight.

A further concern is that incoming President Joe Biden may take more effective control than his predecessor and place the US in some form of lockdown. This is likely to restrict supply – particularly of higher horsepower tractors and broadacre machinery.

“Covid-19 lockdowns are affecting component manufacturers in the supply chain, increased constraints at certain ports and interruptions to shipping are all making things challenging for importers,” says Peter Scott, NZ manager of AGCO New Zealand.

Rural News understands that there is also pressure on new product supply due to the ongoing “mini-boom” being experienced in the Australian market, driven by rains and its government’s capital allowance initiatives. The Tractor and Machinery Association of Australia is reporting year-to-date sales of tractors are up by 22%, with the eventual market likely to top 13,000 tractors – a first since the 1980s.

However, it suggests the Covid situation, resulting in lower production levels, is likely to add 12-16 weeks to typical delivery lead times.

Back in NZ, Alistair Horrocks, Deutz Fahr sales manager for Power Farming, confirms that whole-goods supplies are still flowing into New Zealand.

However, he says the typical six-month lead time from order placement to delivery has now blown out to around eight months.

“Any delays we are experiencing are largely caused by shipping issues, with empty containers hard to come by, finding slots on boats, then sailing being delayed or rescheduled,” he told Rural News.

Horrocks says that while the key German and Italian supply factories are managing the situation well and largely maintaining production levels, Power Farming is having to use extended forecasting to keep supplies arriving for its NZ, Australian and US operations.

Dairy Women's Network (DWN) has announced that Taranaki dairy farmer Nicola Bryant will join its Trust Board as an Associate Trustee.

Rural Women New Zealand (RWNZ) says it welcomes the release of a new report into pay equity.

Red meat exports to key quota markets enjoyed $1.4 billion in tariff savings in the 2024-25 financial year.

Remediation NZ (RNZ) has been fined more than $71,000 for discharging offensive odours described by neighbours as smelling like ‘faecal and pig effluent’ from its compositing site near Uruti in North Taranaki.

Two kiwifruit orchards in the Bay of Plenty and one in Northland are this year's finalists for the Ahuwhenua Trophy competition.

OPINION: A mate of yours truly reckons rural Manawatu families are the latest to suffer under what he calls the…

OPINION: If old Winston Peters thinks building trade relations with new nations, such as India, isn't a necessary investment in…