Amazone unveils flagship spreader

With the price of fertiliser still significantly higher than 2024, there is an increased onus on ensuring its spread accurately at the correct rate.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

Users will have more control during spraying operations with Amazone’s new DirectInject system.

It allows for the inclusion of supplementary crop protection products on the move while spraying.

Claas Harvest Centre Amazone product manager Joshua Patrick says farmers and contractors are constantly faced with new demands during spraying operations. As new products emerge and new technologies develop, farmers and contractors are increasingly asked to apply specific additional products, often to address a particular problem in a localised area of a paddock, or to refrain from spraying a specific product in environmentally-sensitive fields or bodies of water.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

This means operators can now treat specific portions of the paddock with different agents, in just one pass – saving time and money.

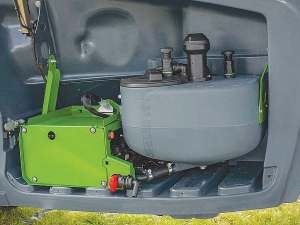

The system consists of an additional 50-litre tank built into the storage compartment located on the right-hand side of Amazone’s UX 01 Super trailed spray unit. Easily filled from ground level, the tank is fitted with its own metering system and incorporates a mechanical agitator to keep the blend homogenous.

The DirectInject feed system can be used with UX 01 single-axle crop protection sprayers fitted with the AmaSwitch or AmaSelect single nozzle control and DUS pro high-pressure recirculation system.

It is activated from the cabin at the touch of a button as operators detect specific weeds that need to be controlled using the supplementary product. The layout of the system keeps the pre-mixed spray agent from the main tank separate from the supplementary plant product by using a second spray line across the boom.

Circulation of the main line is stopped when the secondary direct feed is activated, so product from the main tank is not mixed with the product from the secondary tank.

DirectInject can work with undiluted plant protection agents, allowing unused quantities to be returned to the original container.

Agrisea NZ has appointed Craig Hudson as it's new chief growth officer.

State farmer Landcorp, trading as Pamu, is a forecasting a full-year net profit of around $100 million.

Tony Aitken, chief executive of Ruralco, has been awarded the Excellence in Business Leadership Award at the ANZ Business of the Year Awards.

Global trade has been thrown into another bout of uncertainty following the overnight ruling by US Supreme Court, striking down President Donald Trump's decision to impose additional tariffs on trading partners.

Controls on the movement of fruit and vegetables in the Auckland suburb of Mt Roskill have been lifted.

Fonterra farmer shareholders and unit holders are in line for another payment in April.

OPINION: Here w go: the election date is set for November 7 and the politicians are out of the gate…

OPINION: ECan data was released a few days ago showing Canterbury farmers have made “giant strides on environmental performance”.