Another Windfall for Fonterra Farmers, Unit Holders

Fonterra farmer shareholders and unit holders are in line for another payment in April.

Fonterra is beginning to install new milk vat monitoring systems over the next couple of years.

The aim is to support their farmers’ production of high-quality milk and make the co-op’s milk collection more efficient.

Richard Allen, group director of Farm Source, says the new milk vat monitoring systems are part of Fonterra’s commitment to help make farming easier.

“We’re always looking for the latest technology and tools that can help our farmers, and through The Cooperative Difference we are committed to supporting them in producing high-quality milk in a sustainable way.

“Whether they’re in the milking shed or out in the paddock, this new technology will enable our farmers to monitor their vat from the palm of their hand,” says Richard.

Farmers will be able to choose the type of monitoring solution that best suits their farm. The co-op will cover the cost of the base model and farmers can choose to upgrade and pay their chosen solution provider directly for any extra features.

HALO, Levno, and DTS have been approved as milk vat monitoring system providers. Fonterra is also working with other providers to understand whether their solutions are compatible.

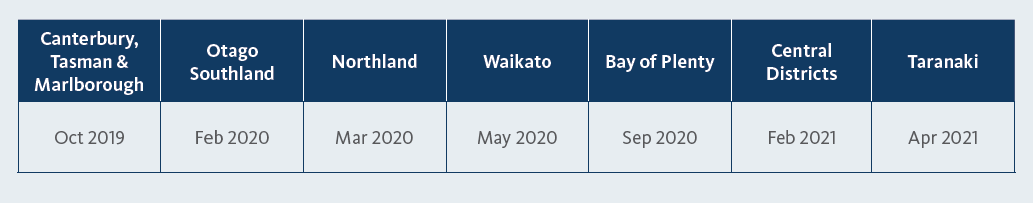

The new milk vat monitoring systems will be rolled out on farms region by region, with installations already well underway in Canterbury, Tasman and Marlborough, and installations soon to begin in Otago and Southland. Taranaki will be final region to get the systems, currently scheduled for installation in May 2021.

Fonterra undertook a pilot programme last season with approximately 80 farms in the Waikato and Canterbury. The feedback received helped to validate assumptions about the benefits that could be realised by both farmers and the co-op.

Farmers who participated in the pilot say it helped them make more informed decisions and address issues quickly.

“I have been farming for 34 years and this makes life easier for both workers and relief milkers. Especially the notifications when the vat chiller has been left off,” says Tirau farmer Adam Wainman.

Winton farmer Peter Hancox says he’d definitely recommend the system to others and Geoff Stevenson, who farms just outside of Christchurch, says the technology was easy to use.

“Really good system, good for watching temps. I’m not a computer buff but easy enough to access,” Geoff says.

Richard says there will be benefits for both farmers and the wider co-op.

“The technology will help farmers make more informed decisions and address issues, quickly helping them to avoid lost milk or grades. By avoiding grades, farmers will also be a step closer to achieving recognition, including Farm Source Reward Dollars, under The Cooperative Difference.

“For Fonterra, the milk vat monitoring systems will help improve collection efficiency as it will provide more precise information about available volume and milking time. This will also save farmers time as they will no longer need to manually update their milking time window throughout the season.”

|

|---|

|

Group director of Farm Source, Richard Allen. |

One month after installation on-farm, milking time windows will begin to be calculated using a rolling monthly average determined by the milk vat monitoring system. Farmers will no longer have to manually update their milking times and Fonterra’s collections will be more efficient.

Fonterra needs a certain level of volume accuracy in order to deliver the collection efficiencies. Many existing systems do not have volume or at the level of accuracy needed. On-going collection efficiencies will result in savings that will fully cover the cost of this new technology.

There will also be benefits of improved milk quality and flexibility in consistently being able to make products that meet customer specifications.

Richard says this kind of support and innovation is another benefit of supplying the cooperative.

“Our co-op sets out to deliver the highest sustainable return to our farmers every day. If we can help our farmer-owners produce the best quality milk, and then transport and process it in the most efficient way, it all adds up to the return we deliver to our farmers and their co-op at the end of the day.”

In addition to the volume and milking time information, Fonterra will also receive a Milk Quality Indicator (farms will also receive this). The Milk Quality Indicator is an estimate of the bacterial level in a vat based on the milking time and temperature data.

The Milk Quality Indicator (MQI) is determined by a theoretical model using the volume, agitation, and temperature profile. Fonterra says the MQI will inform their discussions with farmers to improve milk cooling systems and milk quality where necessary.

Starting September 2021, once all farms have a base model installed and have had time to review their MQI, Fonterra will use the MQI to inform testing. At first this could lead to more grading and demerits as farmers adjust and improve their systems to meet the standard Terms of Supply.

The application of milk cooling grades will continue to be based on the tanker temperature at time of collection but will be based on the more precise milking times. For example, if the tanker arrives to collect the milk and the temperature as assessed by the tanker is not at the appropriate temperature, the farm may receive a grade as per the current Terms of Supply.

The co-op is offering up Smart Finance, a new financial tool that provides low-interest loans in support of improving milk cooling on-farm, until 31 March 2020.

The Government's chief science advisor, Dr John Roche says the key objective for the science sector in the coming year is bedding down the reforms which sees the merger of the previous entities.

Hawke's Bay apple grower Taylor Corporation says a standout 2026 season, coming after a few difficult years, is boosting optimism among growers.

Horticulture New Zealand (HortNZ) has added its perspective to numerous primary sector voices urging the Government to strengthen its draft legislation to replace the Resource Management Act (RMA).

The Commerce Commission has finalised new information disclosure requirements for local councils and water organisations that deliver water supply and wastewater services.

Beef + Lamb NZ (B+LNZ) is calling for significant changes to the Government’s reforms to the Resource Management Act (RMA).

NZPork says the Government needs to strengthen its proposed planning laws to ensure New Zealand's pig farmers can continue to produce pork.

OPINION: Staying with politics, with less than nine months to go before the general elections, there’s confusion in the Labour…

OPINION: Winston Peters' tirade against the free trade deal stitched with India may not be all political posturing by the…