Distributed in New Zealand by Giltrap Agrizone in the North Island and Cochranes of Canterbury in the South Island, HiSpec muck spreaders can handle a wide variety of manures, with the top-end Xcel 1250 capable of dealing with everything from burnt lime to chicken manure to effluent.

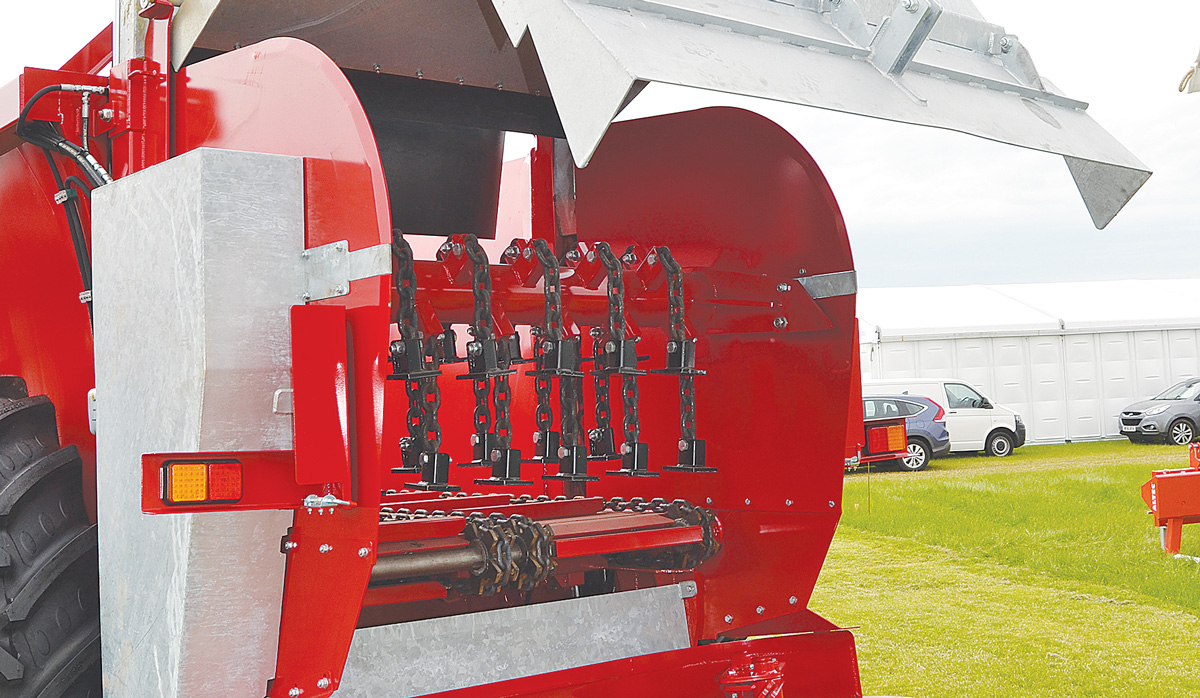

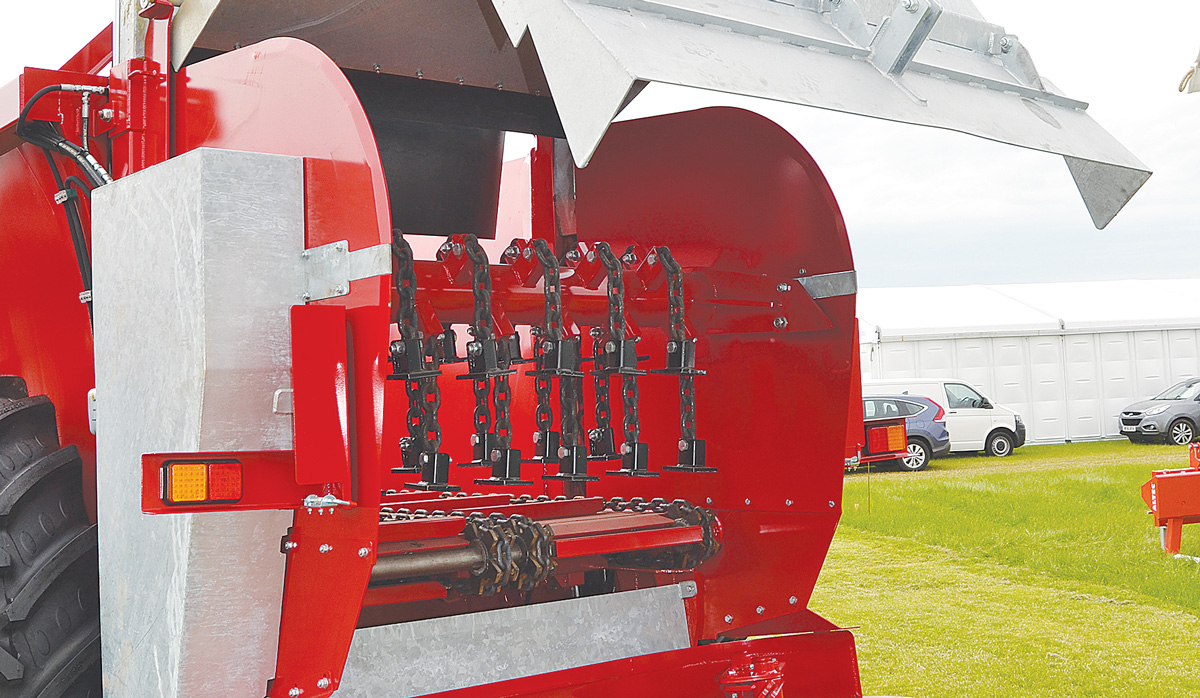

Offering a 12-tonne capacity (14.5cu.m), two floor chains move material to the rear of the wagon, where it meets a horizontal shredding rotor, fitted with 22 freeswinging, heavy-duty Hardox flails.

As they spin, the flails shred the manure against the Hardox hood, ensuring the product to be spread is pulverised before being delivered to the rotary spreading vanes.

The driveline (1000rpm) is directed to a gearbox at the rear of the machine, that in turn uses a chain drive to spin the shredding rotor at over 230rpm. The 1100mm spreading rotors are also driven by the gearbox, to a speed of 520rpm, delivering a spreading width of up to 24 metres, depending on the density of the spread material. The shear-bolt protected rotors are fitted with twin adjustable Hardox steel vanes, with the option of four vanes for lighter materials such as mushroom compost.

Material is moved to the shredding rotor via twin, hydraulically driven floor chains, which feature in-cab speed adjustment to control delivery to the rotor, with the ability to clear a load in less than five minutes.

Weighing in at around seven tonnes, the combined load is carried on 580-70R38 tractor grip tyres, enclosed in galvanised steel mudguards.

|

|---|

|

Featuring automatic chain lubrication and a centralised greasing system, maintenance is kept to a minimum.

|

The unique rotor and chain design allows stones or foreign objects to pass through more easily than vertical auger machines, while the intensively processed material can be spread finely and evenly to be utilised by plants, while at the same time reducing the turnaround back into the grazing cycle.

Featuring automatic chain lubrication and a centralised greasing system, maintenance is kept to a minimum, while hydraulic braking and LED lighting ensures safe operation. Optional equipment includes “greedy” boards for bulkier materials, while GPS mapping and weigh cells can be used to provide proof of placement and spread volumes for regulatory authorities.

www.gaz.co.nz