I am sure even though we may want to forget it, last season will be one we will remember for a long time. Most of us survived it and for most regions the summer was very good for plant growth.

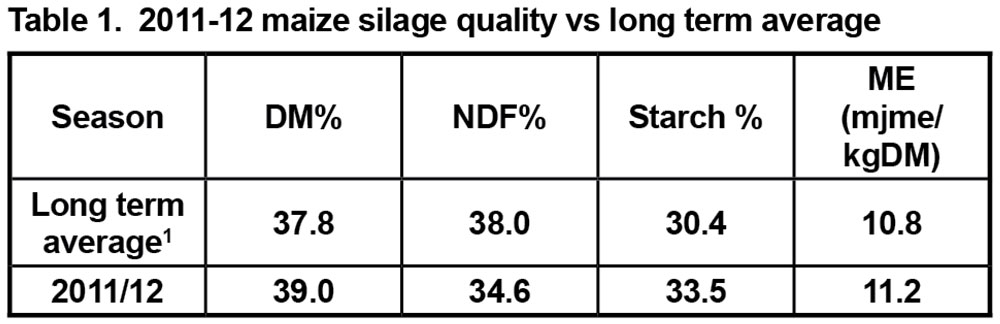

And we also remember the good times. One of the great maize silage seasons was 2011-12. We had everything great maize needed – heaps of heat, sun and moisture at the right time. As a result farmers produced outstanding maize silage, as reflected in Table 1 (see below).

The exciting thing is that this current season is looking to be like 2011-12. In nearly every region, high temperatures, lots of sunshine and adequate rainfall after flowering has meant we are looking at fields of high yielding, high quality maize silage.

Moist soils have meant that plants are still green, and the cobs are rapidly filling with starch. In fact, many farmers will be able to take their maize to almost full starch and yet still have enough moisture in the plant to ensure great compaction and fermentation of the harvested maize silage.

How do you ensure you make the most out of a season like this? There are four things you need to do:

How do you ensure you make the most out of a season like this? There are four things you need to do:

1. Get the crop checked by your merchant and communicate with your contractor now. With the extra heat in the day followed by cool nights, the maize will be maturing reasonably quickly. Ask your contractor or merchant to walk your crop and give you some idea when it will be ready for harvest. Then give your maize contractor a ring and let him know so he can schedule you in.

2. Harvest the maize crop when it is ready. We often says that when the kernel is two-thirds hard starch and one-third soft starch it is ready to harvest. This season that guideline is probably not too important. Because most areas have been getting regular rain and the crops are still green, maize silage can be harvested safely from the two-thirds milk line to full starch (i.e. black layer) as long as there is enough moisture in the plant to allow fermentation to occur.

3. Make sure the kernel processor/shredder is working well. With such high starch levels and potentially hard kernels, it is vital that all kernels are broken into pieces as small as possible. This requires the harvester to have tight kernel processing or accurate shredding.

4. Apply a proven inoculant that will prevent heating at feed-out. With high starch levels present in the maize silage, there are also likely to be high lactic acid levels in the maize silage. This can make controlling heating during feed-out difficult. A product like 11C33 contains L. buchneri which helps reduce the likelihood of heating occurring during feed-out.

Buying in maize silage

Some farmers have written in their contracts that maize silage needs to be delivered at 32 - 38% DM (dry matter). This season maize silage buyers need to consider what is driving the DM of their maize. If it is drought or disease, then you are likely to get drier plants. However, if it is because of lots of grain in the maize silage, as we saw in 2011-12, it is possible dry matter will exceed 40% as the grain is drier and makes up a larger proportion of the total plant.

If the maize silage you are buying in is 40% DM and 35% starch, be thankful for the extra starch and the extra quality you are getting. In fact, you may want to buy your grower a bottle of wine to thank him. Ultimately, higher quality maize silage will mean more milk in the vat and more money in your pocket.

• Ian Williams is a Pioneer forage specialist. Contact him at This email address is being protected from spambots. You need JavaScript enabled to view it.