LINCOLN UNIVERSITY Dairy Farm has bucked the trend of its high performance peers and increased operating profit.

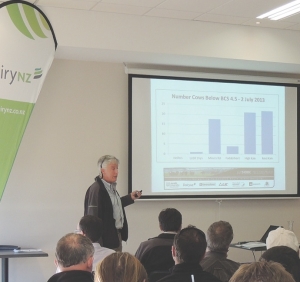

Figures presented earlier this month at the third of its focus days for the year show it boosted the bottom line $112/ha to $4665/ha while the four farms it benchmarks with saw operating profit fall (see table).

“Not only was there a lower milk price but it was a harder season to farm through,” noted DairyNZ productivity development manager Steve Lee, a member of LUDF’s management team, as he introduced the figures.

LUDF managed to shave 8c/kgMS off its operating costs while the others’ costs increased, although LUDF started from a 2011/12 figure “head and shoulders” higher than its peers, at $4.30/kgMS.

A tough spring, irrigation restrictions, higher feed costs and lower pasture production due to clover root weevil were among the challenges the peer-group farms cited as reasons for their figures, Lee said.

At $4.22/kgMS LUDF’s costs in 2012/13 were mid-table for the five farms.

“Our cost per kilogramme of milksolids is still relatively high and we need to be seeking ways to tidy it up and get our cost structure a wee bit tidier if we can,” Lee said.

Unusually for the July focus day, no budget for the coming season was presented as the bones of it were addressed at the May focus day (Dairy News, May 14).

At that, SIDDC executive director Ron Pellow unveiled a nitrogen cut from 350kg N/ha to 260kg N/ha, with no application greater than 25kg/ha. That will save $31,000, but a provision for up to $55,000 on bought-in feed has been made to compensate for the possible shortfall in pasture production. No eco-n applications will save $48,000.

At this month’s field day, Lee touched on some other areas exercising the management team’s minds, such as wintering costs. “Our graziers do a great job for us but is the model [of grazing off] really working for us and do we have options going forward?” he asked, rhetorically.

At 25-27c/kgDM, the price LUDF is paying for winter crop, either kale or fodder beet, is “at the high end”, he maintained.

However, one farmer present suggested that was cheap for Canterbury, and another said winter grazing rates needed to be at least that or the crops wouldn’t be grown.

Overall, at 90c/kgMS, LUDF’s wintering and replacement costs were equal top. Lee highlighted Slee’s 10-20c/kgMS figure. “They’re spending a whole lot less. They are positively deviant these people.

“They are doing something really good we can learn from… they own and control all of their dairy support.”

But having said that, he added LUDF is not “about to run out and buy a support block” and per-cow costs (ie animal health, breeding, wintering and replacement costs) of about a quarter of total operating costs are “reality and something we have to live with.”

A smaller herd – LUDF now has 630 cows compared to 670 on average historically – should help “keep a lid on per cow costs,” noted Pellow. With fewer replacements, total animals owned will be down to about 950 in future, from about 1060 in the past, added Lee.