Every dairy farmer knows dairy effluent contains valuable nutrients. And they know that what happens to water on the land, whether from rain or irrigation, has a direct correlation to what happens with dairy effluent.

Put simply, there is no question the wet stuff is all interrelated.

The question has been only about what is the value of water in general, and effluent in particular, because until now no technology has existed -- in any meaningful way -- to allow pulling together all the information onto a single platform to make sense of the relative value of effluent, water and fertiliser.

But that is changing, with the launch of MyBallance in partnership with Precision Farming.

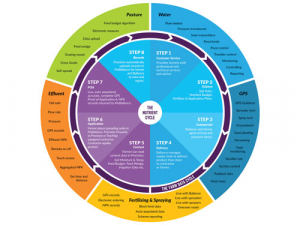

MyBallance is the newly released farm management platform for nutrient management, compliance and sustainability. It provides start-to-finish technology for the planning, purchase, application and recording of farm nutrients. This is sometimes referred to as the ‘nutrient core’, i.e. the central piece of the annual cycle for maximising the value of nutrients.

Precision Farming’s role as MyBallance exclusive technology partner is to bring notification-to-spreader and proof-of-application electronic resources to this nutrient core; that is the purpose and value of MyBallance.

And the key to the value of MyBallance is that all stages of the nutrient core or nutrient cycle is that every step is now electronic.

That means plans, orders, instructions and records are all created and recorded electronically, not on paper or diaries whose data contents must later be transferred into some system to enable sense to be made of it all.

MyBallance enables farmers to manage all stages of the nutrient cycle (the core of best-practice nutrient management) electronically so that records are live, automatic, complete and accurate.

Now, with that nutrient core available to all Ballance customers, Precision Farming adds an ‘outer ring’ of complementary services that bring ‘the wet stuff’ into focus.

Farm water -- for irrigation, stock water and dairy shed water, and dairy effluent -- can now be measured, monitored, controlled and reported within the same system, in context with the MyBallance Nutrient Core. This greatly increases dairy farmers’ profitability, productivity, compliance and sustainability.

Let’s start with profitability and look at water usage for example. It’s an old saying that you can’t manage what you can’t measure, never more true with farm water. If a trough or tank is leaking and spilling thousands of litres annually, a simple flow meter will tell if water is flowing more than expected between 1am and 3am.

New low power sensors are now so affordable -- just a couple of hundred dollars each -- that it is highly profitable to know what water is being used where, and how staff can be supported to cut back on water they may not even know is being wasted.

Second, consider productivity. Irrigation without fact-based decisions on soil moisture and impending rainfall is guesswork, and can lead to over- or under-watering, both of which incur increased cost or decreased growth, or both.

Colour-coded

Staying with productivity, effluent when tested for nutrients and measured by flowmeter for volume, and tracked by GPS for application, leads to known quantities of nutrients applied when and where.

Because the Precision Farming third generation effluent fail-safe system measures flow, GPS and time, not only can the farmer see on the Precision Farming website colour-coded paddocks for effluent management, but also the Precision system generates electronic records that are ready to be directly loaded into MyBallance. This means that going into the new season the annual plan for effluent and non-effluent areas can be directly costed, showing the real financial benefits of integrated NPK data.

And for compliance and sustainability, accurate, fact-based, audit-quality data makes for easier preparation of compliance records for national and regional council reporting, all within the MyBallance Precision partnership.

• Kenneth Irons is managing director of Precision Farming Ltd, Canterbury and West Coast.