Until now the possibility of taking data from existing mechanical implements and feeding the information into farm management systems has been a pipedream for most farmers.

But the German manufacturer Lemken has cracked it.

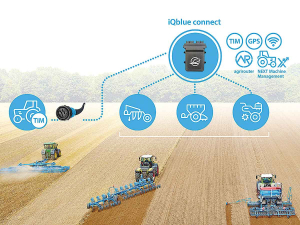

The company’s iQblue connect is a retro-fit kit that connects implements and existing machinery with Tractor Implement Management (TIM) systems.

This allows many functions of basic mechanical implements to be automated and integrated into digital documentation.

It works on the basis that TIM performs work functions which are triggered by the implement. Operators only require a single iQblue connect module, which can be used with a range of implements.

The module connects to the tractor via an ISOBUS interface, and has GPS and a mobile data connection for communication, for example, to the farm management system.

Data is transmitted via the agrirouter, a cross-manufacturer platform for exchanging data between machines, farmers, contractors and software applications.

Depending on the intended use, a sensor kit is permanently installed on the implement to record the required information and pass it on to the iQblue connect module. This means no further equipment is required as the tractor is used for controlling implement functions.

For example, a plough is fitted with a sensor to determine the current working width, from where iQblue connect calculates the target working width from the GPS position and transmits this information to the tractor. The variable working width is then adjusted via the tractor’s hydraulic system.

In the case of semi-mounted cultivators, working depth can be detected by a sensor, then it combines with target working depth from maps provided by the agrirouter to subsequently send a command to the tractor to adjust the working depth.

A single iQblue connect module can be transferred quickly and easily from one implement to another without special tools, automatically adapting to the implement it is connected to at any given time.

www.lemken.com