While the new Coalition Government sorts out the previous administrations’ emissions policy, emerging UK technology companies are indicating where things might be heading.

Lincoln-based (that’s the one in the UK) Crop Intellect, claims its technology lets crops turn pollution into fertiliser, using a new technology that captures air pollution and uses sunlight to convert it into nitrate on the leaf surface of a crop.

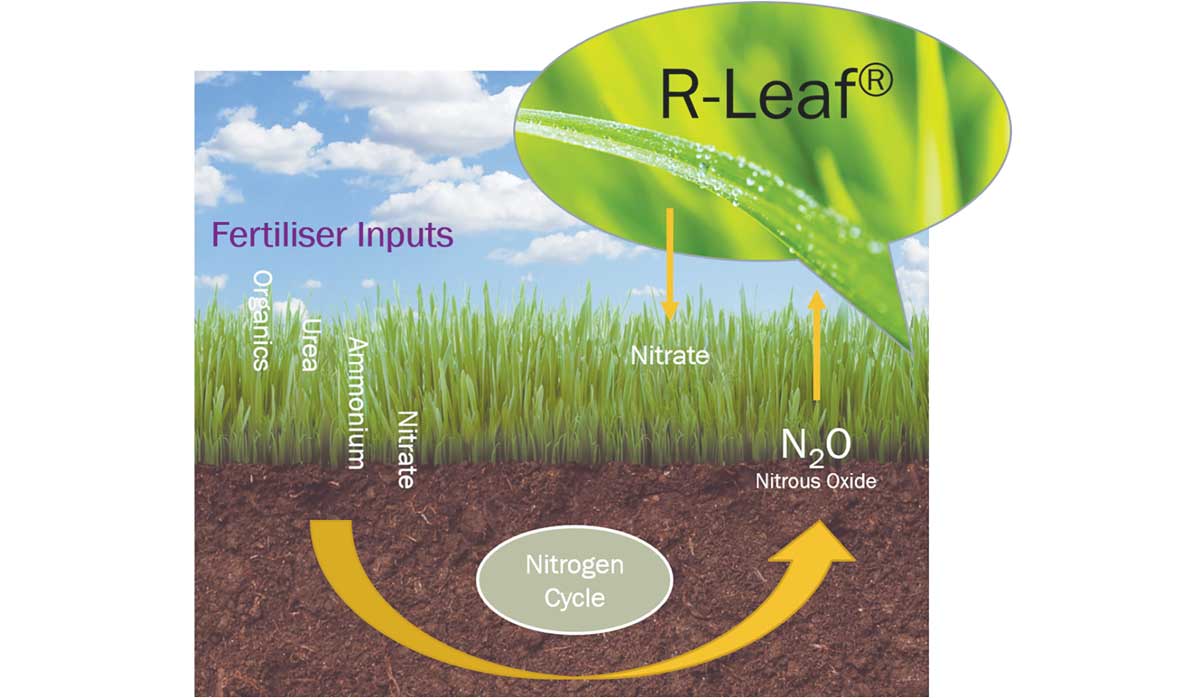

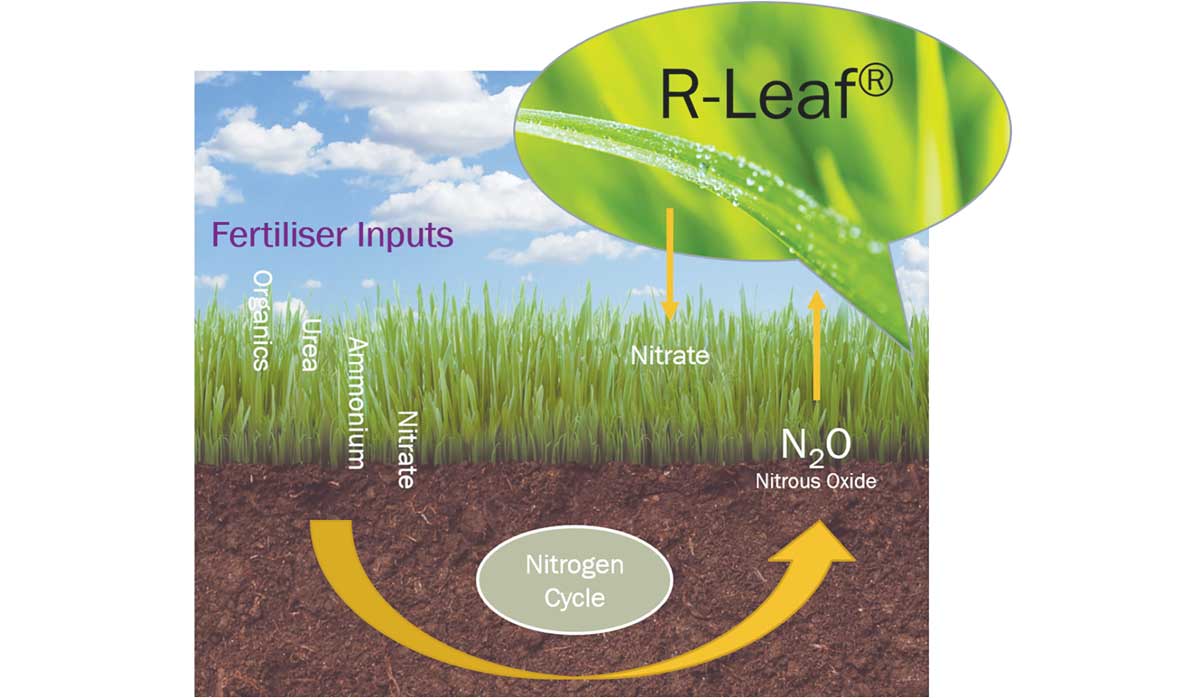

Called R-Leaf, a process known as photocatalysis breaks down nitrous oxide, turning it into an essential crop nutrient, potentially reducing farm emissions and ultimately the industry’s reliance on synthetic nitrogen.

Against a background of rollercoaster fertiliser markets and environmental concerns, with the promise of more volatility still to come in the case of the former, the technology is being promoted as a development that will allow farmers to make better use of nitrogen fertiliser, while reducing the greenhouse gas emissions associated with its use.

Classed as a fertiliser, R-Leaf is based on titanium dioxide and comes in a liquid formulation that also contains manganese, molybdenum and zinc. It can be applied through a standard farm sprayer to crop foliage, either on its own or as part of a tank mix. Once applied, it uses sunlight to convert atmospheric nitrous oxide into nitrate, which the company says helps to provide the plant with a constant supply of the nutrient.

The patented photocatalyst technology contained in R-Leaf has been designed to work under normal daylight conditions, rather than needing high intensity light usually associated with such chemical reactions, this allows it to react with nitrous oxide in field conditions, breaking the pollutant down into nitrate, carbon dioxide and water – all of which are required by the plant.

Jeremy Hitcham, commercial manager at Crop Intellect, says that for growers wishing to reduce the carbon footprint of their business or with carbon trading in mind, R-Leaf’s potential to contribute towards reducing climate change has been validated at 5.4t/ha of carbon dioxide equivalent when used at a rate of 2 litres/ha – verified by the Climate Impact Forecast tool.

Hitcham suggests two ways in which R-Leaf can be used on-farm: The first is to reduce bagged nitrogen usage by 25% and let R-Leaf providing the rest, so that yields are maintained; the second, maintain normal farm practice and apply the same amount of nitrogen, with R-Leaf being used to provide additional yields.

|

|---|

|

R-Leaf, a process known as photocatalysis breaks down nitrous oxide, turning it into an essential crop nutrient.

|

Currently being applied to many thousands of hectares, R-Leaf currently costs £25/litre, with split applications of 2 litres/ha recommended for cereals crops, with applications at growth stage T1 and T2, meaning a total cost of £50/ ha. The second application is needed because R-Leaf doesn’t move once it has been applied, so a growing plant producing new leaves benefits from the follow-up as older, treated leaves become shaded.

Suffolk sugar beet grower Frank Stennett trialled R-Leaf on some of his crop last year and recorded a 6% increase in yield. Helped by the use of irrigation in a hot, dry growing season, untreated sugar beet gave an impressive yield of 106.15 t/ha, while the portion of the crop that had received 2 litres/ha of R-Leaf had an average yield of 112.28 t/ha.

The cost of using the innovative product at 2 litres/ha was about £40/ha, recalls Stennett, which was easily covered by the additional 6t of beet at a 2022 price of £27/t.

Stennett, opted to remain with to his standard application of 120 kg/ha of bagged nitrogen, then applying 2 litres/ ha of R-Leaf, rather than using it to reduce nitrogen use.

He also applied R-Leaf to winter wheat, but despite the farm’s light soils and the season’s high temperatures, recorded his best-ever wheat yields in 2022 at levels more than 10 t/ha.