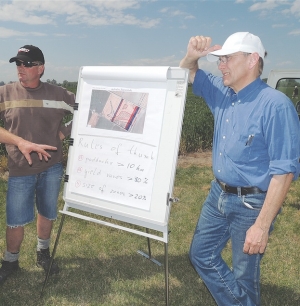

Foundation for Arable Research field day guest speaker Armin Werner, of Lincoln Agritech, suggests three ‘rules of thumb’ to determine whether such zonal management is worthwhile (see box).

“If you have fields that fit those criteria then you should at least be thinking about trying zoning,” he said, suggesting a high, low and medium zone approach as a simple starting point.

That could be done from yield maps or simply from the in-depth historic knowledge of paddocks most farmers accumulate. Another way might be EM [electro-magnetic] mapping of soil, which correlates with water holding capacity.“It’s a cheap one because it’s very fast,” he noted.

Once a map with zones is produced, it can be used to alter input rates for seeds, fertilisers and other inputs. While low yielding areas typically require less phosphate or potash fertiliser because less is removed from the soil with the crop, with nitrogen the reverse may be true, and higher nitrogen rates on those areas may go some way to bringing yields up, as FAR trials had shown.

However, that would depend on the limiting factor for yield, and Werner stressed often that is water. “The physical property that’s the most important and that you can’t change is the soil water storage capacity.”

Challenged on that, he acknowledged organic matter could be increased by management, and hence water holding capacity, but said at best extra organic matter might add 20% water holding which for a soil with a potential 100mm of plant available water, would still only be an extra 20mm.

In some areas of Germany, Werner’s homeland, farmers rely completely on yield maps for their zone management because every year they have dry summers and water is always the limiting factor, he added.

Fellow field day speaker, North Otago farmer Pete Mitchell, explained why water, or rather variable rate irrigation, is where they started with zone management.

Of seed, chemical and fertiliser, water was the greatest cost – about $800/ha if they applied 200mm; and when they investigated the potential payback from varying irrigation rates it offered the quickest return.

As such it best fitted their decision ‘tree’ for zonal management, which prioritises projects by the expense of the inputs involved, the likely time to payback on adopting a zoned approach, and productivity gains that might be achieved.

Mitchell says they’ve been calculating payback periods purely on savings because while there probably will be yield gains, these are hard to predict and quantify.

EM mapping of the soils under irrigation revealed water holding capacity ranging from 34mm to 114mm, yet they’d been using a uniform water rate right around the pivot. By tuning irrigation to soil water holding capacity they’ve since slashed water take from 3L/second to a maximum 24L/second, a 27% saving, and sometimes as low 11L/second.

Also, by avoiding over-watering, it’s saved labour because pivots no longer get stuck on hills and it’s eliminated the environmental, not to mention consent-breaching, problem of run-off.

Based just on that reduced maximum take, the saving is $216/ha, or about $18,000 on the area covered by the modified 510m pivot, Mitchell calculates.

With a cost of about $100/m of pivot to fit the variable rate technology and install the necessary control software, the payback will be three-five years based on saving alone.

“But you’ve got to have someone with a passion for it to drive [the installation] for you because it is quite complicated,” he warns.

Mitchell’s also had soil grid sampled to identify and remedy pH, phosphate and potash variation, in one area saving $170/ha on phosphate fertiliser, though in another an extra $10/ha was needed to raise pH.

Werner stressed that variability within a paddock, particularly as paddocks are made bigger to accommodate modern machinery and increase work rates, can be as great as across 20,000ha. “This we have to face and we have to handle.”

He says in Australia already at least 50% of cereal growers are using variable rate application for fertiliser and at least 30% are varying seed-rate within paddocks, albeit across typically much larger paddocks than New Zealand’s.