Berry supplier The Fresh Berry Company has rolled out a locally developed forecasting platform that will allow its growers to precisely plan planting and harvest times, to ensure fruit hits store shelves when consumers most want it.

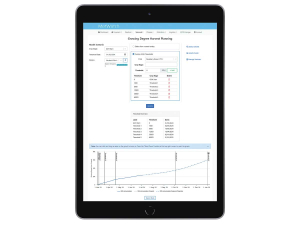

Developed by Kiwi agritech company Hort- Plus, the Berry Harvest Planning Tool combines regional weather data with berry-specific growing models for key varieties of strawberries, raspberries, blueberries and blackberries supplied by The Fresh Berry Company.

Developed by Kiwi agritech company Hort- Plus, the Berry Harvest Planning Tool combines regional weather data with berry-specific growing models for key varieties of strawberries, raspberries, blueberries and blackberries supplied by The Fresh Berry Company.

“100%, this gives us the edge by bringing more accuracy and confidence to our forecasting and harvest planning,” Astill says.

“It’s a great tool for our sales team and it gives our agronomists and growers the data they need to stagger planting to achieve harvest at optimum times for consumer demand, including at times of year when some berries are traditionally difficult to find in stores.”

The tool based its projections on ‘growing degree hours’, a measure for the number of hours above a base threshold temperature that a berry or fruit needs to be exposed to grow and ripen for harvest. This was more accurate than the ‘growing degree days’ measure used by many others in the industry and allowed for increased precision.

Astill says that in the past, planting and harvest planning was commonly done by The Fresh Berry Company agronomists using spreadsheets that took hours or days to create. The new digital tool “supercharged” that process by allowing different planting and harvest scenarios to be run in just a few clicks.

Astill says that in the past, planting and harvest planning was commonly done by The Fresh Berry Company agronomists using spreadsheets that took hours or days to create. The new digital tool “supercharged” that process by allowing different planting and harvest scenarios to be run in just a few clicks.

“It saves so much time and the other beauty of it is that the models are dynamic. As the weather and forecast changes the projected harvest timing updates – it’s not static like a model created in a spreadsheet.”

“The Harvest Planning Tool does all the heavy lifting and data crunching, so The Fresh Berry Company staff don’t have to. It’s a great example of the value digital tools can add – anyone can collect data but making it useful and usable is often the hard part.”

Barley says the tool had potential to positively impact the berry market. Greater certainty around harvest times could also have downstream benefits for labour and workforce planning, he says.

“There’s huge potential for us to work with The Fresh Berry Company and others across New Zealand’s horticulture industry to create similar solutions for other fruit and crop types.

“Chill units is another measure we could easily visualise and model for huge benefit when it comes to dormancy breaking, flowering and harvest planning for other crop types.”

Astill says the new tool was the latest in a string of innovations introduced by The Fresh Berry Company. The company will continue investigating opportunities to harness innovation that drives quality, sustainability and grower profitability which soon could include robotics in its operations.

Astill says the new tool was the latest in a string of innovations introduced by The Fresh Berry Company. The company will continue investigating opportunities to harness innovation that drives quality, sustainability and grower profitability which soon could include robotics in its operations.

“We are committed to ensuring our customers and consumers have a delightful eating experience with the berries our growers grow. It’s a privilege to deliver these experiences and there’s a real sense of responsibility within our team to consistently achieve that goal.”

The Fresh Berry Company is New Zealand’s leading supplier of berries, with its sister company Berry Farms NZ operating out of Hawke’s Bay and a network of independent growers in Bay of Plenty, Waikato and Northland.