The Innovation and Quality awards are based in the Napa Valley and aim to recognise innovation’s that lead to high quality and ultra-premium winemaking. For VinWizard the acknowledgement that their Multi-Level-Probe (MLP) was considered the best, was a welcome surprise.

Owner/founder David Gill says the probe which was developed in Marlborough, provides winemakers with an added tool when it comes to fermentation. It is especially useful in red winemaking, and has been eagerly adopted by 160 wineries world-wide.

The process, which seems ridiculously simple, makes you wonder why someone hasn’t thought of it before.

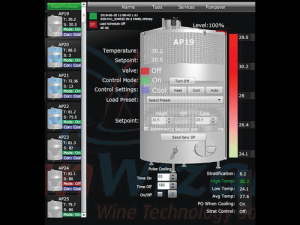

A stainless steel pole, with up to 32 sensors inside, is placed inside a stainless steel or oak tank. Each of the sensors monitors the current temperature of the fermenting juice, allowing the winemaker to make decisions about pumping over well in advance of anything going wrong.

The MLP shows a cross section of all the temperatures along a vertical cross section of the tank, all the way from the top to the bottom.

“This is the first time we have been able to see inside a tank, to see what is happening in the layers of juice,” Gill says. “In the past it has always been guess work.”

In winemaking it is vital that the temperature remain consistent throughout the fermentation, but Gill says there are issues with traditional methods such as pumping over.

“It can be fermenting along nicely and then they pump it over and all of a sudden the ferment stops. We have seen that happen a lot in America – and it’s because there is this big plug of cold juice at the bottom of the tank. With the MLP we can anticipate that and set up the pump over before it becomes an issue.”

Every winery tank has different points of ferment activity, Gill says, depending on the refrigeration effectiveness and the tank design. Each requires pump overs to ensure the ferment is mixed and oxygenated, while maintaining a consistent temperature. The problem he says is how often and how long should those pump overs be?

“They are often based on assumptions. Now the winemaker can dynamically see the effects of pump overs in the entire tank.”

The ability to control those actions has seen a significant decrease in power consumption for wineries Gill says – between 30 and 50 percent. While the majority of clients are utilising the probe for red winemaking, the cost benefits for white wine like Sauvignon Blanc are also high.

“With Sauvignon Blanc you don’t need to agitate a tank continuously. With the MLP you can see the layering and do something about it when it happens in real time. Just run the agitators for an hour and stop – they don’t have to run 24/7 to keep the tank mixed.”

While the current probes are for 50,000 litre to 100,000 litre tanks, Gill says they are currently working on a new probe that will be suitable for oak barrels.

“This will be a wireless probe, working on the same principle. We should be releasing that in the next six months.”

Maybe a second innovation award could be on the cards in 2019.

This email address is being protected from spambots. You need JavaScript enabled to view it.