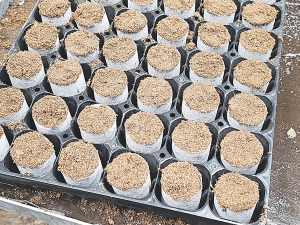

Biodegradable paper pots or cells hold individual seedlings, which are planted directly into the ground without disturbing the roots of the crop. While reducing carbon footprint is one thing, early adopters of paperbased growing systems are also singing its praises for faster production and healthier root development.

Automating the process of large-scale propagation is not new. However, Swedish company BCC FiberCell can now deliver an environmentally friendly solution that also stacks up economically.

Distributed in NZ by PrimeHort, the latest FiberCell Paper Pot machines, paper pots and tray holders are suitable for most NZ crops.

PrimeHort points out that FiberCell Paper Pots are 100% biodegradable at varying levels to suit crop requirements, from as little as 4-6 weeks through to 12 months. The pots air-prune roots as they grow towards the pot’s edge, preventing root circling, to encourage healthier root systems and better/faster plant growth.

Other benefits include planting the paper pot directly into a next-stage environment, thus removing transplant shock. The fact that paper is porous, allows for good water drainage and aeration, which prevents waterlogged soil and promotes robust root development.

The first machine order was recently placed by Annton Nursery Ltd in Cambridge. The nursery supplies garden centres around NZ with a mix of perennials, edibles, trees and shrubs. The company is one of NZ’s most respected and largest wholesale nursery operators.

It had been using a similar product to a jiffy pot, with all cuttings and seedlings put into paper plugs, and after establishing a root base, the team would transplant them into bigger pots.

Already embracing nursery automation, Annton Nursery managing director Steve Burton was also looking for a sustainable solution to support his propagation efforts.

However, the productivity, quality and profit formula had to stack up. He says introducing paper pots will speed the process up, while enabling more robust, healthier plants.

The Annton team also like that each little paper pot provides its own perfect growing environment. Because the paper degrades naturally, the seedling can stay in the pot when transplanted into a bigger environment, removing transplant shock. As the paper degrades at different rates, growers can select the level of paper to suit their crop.

Burton says a further reason for choosing a FiberCell Paper Pot Machine was the upcoming expansion into strawberries.

With automation achieving about 7000 pots per hour – and only one or two workers monitoring the machine as it forms the pots and places them directly into tray holders – the innovative system dramatically reduces labour requirements, while also providing certainty around crop uniformity, quality and output.

“We’ve been using paper pots for nearly 10 years and think they are a significantly more efficient and effective way to propagate,” Burton explains. “Moving to our own machine has been driven by the increased volumes we will need for our new strawberry facility.”

This will produce over one million young strawberry plants in its first season, with capacity to increase in subsequent years.

The plants are all produced in a six-week window, which means a machine capable of producing up to 35,000 paper pots per day is needed – something that is easily achieved by the two row FiberCell machine.

Burton goes on to explain that for the remainder of the year, the operation required a machine that could increase efficiencies in their regular ornamental program.

The nursery will now produce its own 4cm pot for internal perennial propagation.

Meanwhile, the second row outside of the strawberry season will be converted to a larger 6cm diameter pot that will be dibbled and inserted with rooted plugs of its shrub lines to eliminate the manual tubing.