Amazone unveils flagship spreader

With the price of fertiliser still significantly higher than 2024, there is an increased onus on ensuring its spread accurately at the correct rate.

Amazone has unveiled three innovations in its latest range of sprayers to achieve application accuracy across the entire working boom width.

Amazone has unveiled three innovations in its latest range of sprayers to achieve application accuracy across the entire working boom width.

German farm machinery manufacturer Amazone has unveiled three innovations said to achieve unprecedented application accuracy across the entire working width of the boom.

Suitable for all Amazone sprayers equipped with Super-L2 booms from 27 to 40m, ContourControl and SwingStop systems control vertical and horizontal boom movement respectively.

And the SwingStop Pro takes the concept a step further by adjusting the output of each nozzle according to its speed.

Used individually or combined, the systems are said to offer unprecedented levels of application accuracy over the entire boom by compensating for any vertical or horizontal movements of the sprayer boom.

ContourControl uses six boom-mounted ultrasonic sensors and a fast-responding hydraulic system to maintain boom height. With the two outer sensors controlling the independent angling of the left-hand and right-hand booms, and the two middle sensors regulating the height of the boom, it is guided in its height by the parallelogram. A hydraulic accumulator on the boom provides short reaction times -- literally in a fraction of a second.

The system also allows the negative angling of the outer boom sections to maintain the determined application height in all conditions, such as when the booms dip below the horizontal plane – useful if the sprayer passes over a ridge.

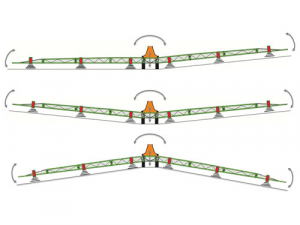

SwingStop is an active yaw stabilisation system that maintains the horizontal boom position during fast travel over ground undulations, or during turning, accelerating or high speed. All these can put booms under enormous strain, causing the boom ends to swing backwards or forwards. This can affect application rates, with forward movement causing under-dosing and backwards motion overdosing, the results of which can be readily seen in heavier crops; this is even more pronounced with the use of wider booms.

While most sprayers use passive buffer or damper systems to minimise yaw, the SwingStop system uses boom-mounted acceleration sensors to determine the horizontal position of the boom relative to the forward speed of the sprayer. Two actively operating hydraulic rams in the centre section of the boom then counteract any detected movements to ensure the boom rides smoothly.

SwingStop Pro uses the same data to adjust the output of each individual nozzle relative to the forward speed of the sprayer, using pulse width frequency modulation (PWFM) nozzles controlled by valves with a high frequency range of 50Hz. High speed switching means the valves can be opened or closed in two milliseconds, and the application rate can be adjusted from 30 - 100% over the same time.

In practice, if the nozzle is moving quicker than the sprayer, the opening time and application rate is increased for a short time. However, a nozzle moving slower than the sprayer will remain closed longer, so reducing the application but maintaining spray pressure and droplet size.

Fonterra’s impending exit from the Australian dairy industry is a major event but the story doesn’t change too much for farmers.

Expect greater collaboration between Massey University’s school of Agriculture and Environment and Ireland’s leading agriculture university, the University College of Dublin (UCD), in the future.

A partnership between Torere Macadamias Ltd and the Riddet Institute aims to unlock value from macadamia nuts while growing the next generation of Māori agribusiness researchers.

A new partnership between Dairy Women’s Network (DWN) and NZAgbiz aims to make evidence-based calf rearing practices accessible to all farm teams.

Despite some trying circumstances recently, the cherry season looks set to emerge on top of things.

Changed logos on shirts otherwise it will be business as usual when Fonterra’s consumer and related businesses are expected to change hands next month.