Amazone unveils flagship spreader

With the price of fertiliser still significantly higher than 2024, there is an increased onus on ensuring its spread accurately at the correct rate.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

Users will have more control during spraying operations with Amazone’s new DirectInject system.

It allows for the inclusion of supplementary crop protection products on the move while spraying.

Claas Harvest Centre Amazone product manager Joshua Patrick says farmers and contractors are constantly faced with new demands during spraying operations. As new products emerge and new technologies develop, farmers and contractors are increasingly asked to apply specific additional products, often to address a particular problem in a localised area of a paddock, or to refrain from spraying a specific product in environmentally-sensitive fields or bodies of water.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

This means operators can now treat specific portions of the paddock with different agents, in just one pass – saving time and money.

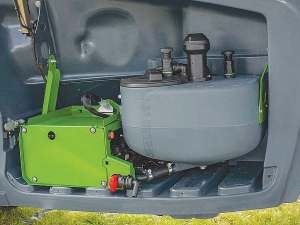

The system consists of an additional 50-litre tank built into the storage compartment located on the right-hand side of Amazone’s UX 01 Super trailed spray unit. Easily filled from ground level, the tank is fitted with its own metering system and incorporates a mechanical agitator to keep the blend homogenous.

The DirectInject feed system can be used with UX 01 single-axle crop protection sprayers fitted with the AmaSwitch or AmaSelect single nozzle control and DUS pro high-pressure recirculation system.

It is activated from the cabin at the touch of a button as operators detect specific weeds that need to be controlled using the supplementary product. The layout of the system keeps the pre-mixed spray agent from the main tank separate from the supplementary plant product by using a second spray line across the boom.

Circulation of the main line is stopped when the secondary direct feed is activated, so product from the main tank is not mixed with the product from the secondary tank.

DirectInject can work with undiluted plant protection agents, allowing unused quantities to be returned to the original container.

One of New Zealand’s longest-running pasture growth monitoring projects will continue, even as its long-time champion steps away after more than five decades of involvement.

The Insurance & Financial Services Ombudsmen Scheme (IFSO Scheme) is advising consumers to prepare for delays as insurers respond to a high volume of claims following this week's severe weather.

Additional reductions to costs for forest owners in the Emissions Trading Scheme Registry (ETS) have been announced by the Government.

Animal welfare is of paramount importance to New Zealand's dairy industry, with consumers increasingly interested in how food is produced, not just the quality of the final product.

Agriculture and Forestry Minister Todd McClay is encouraging farmers and growers to stay up to date with weather warnings and seek support should they need it.

The closure of SH2 Waioweka Gorge could result in significant delays and additional costs for freight customers around the Upper North Island, says Transporting New Zealand.