Waikato dairy effluent breaches lead to $108,000 in fines

Two farmers and two farming companies were recently convicted and fined a total of $108,000 for environmental offending.

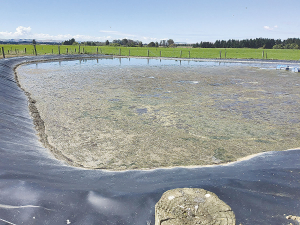

10 days after adding Biostack, the sludge has lifted from the base of the pond and the odour has noticeably reduced.

10 days after adding Biostack, the sludge has lifted from the base of the pond and the odour has noticeably reduced.

Handling the challenges of effluent management could become easier with a new product that allows dairy farmers to treat their effluent systems as a routine part of weekly milking shed maintenance.

The product comes in a liquid form and can be added to the effluent system through the existing drain in the dairy yard, says Richard Kettle of AHD Nutrition Division.

The core microbial technology is known as a photoautotroph, he says.

"In 'farmer' terms, this product has bacteria that activate and do their work when the sun is shining. Particularly effective in an effluent pond system where there is large reflective surfaces and sunlight.

"Biostack also holds onto micronutrients like nitrogen and phosphorus during dormancy. This means that when you pump effluent on the paddock or emerging crops you are taking the micronutrients to the plant, fostering additional growth."

The bacteria have a shelf life of three years when unopened; once the containers are opened it must be used within a six month period.

Kettle says Biostack users would notice a reduction in odour within two weeks of using the product and there will be little to no crusting on the pond surface. He says the product has the ability to break down both surface and bottom solids and effluent is easier to pump.

Kettle says farmers will notice an improvement in paddock performance after irrigation.

"Local experience has shown that some effluent ponds are under capacity and have massive sludge build up, even to the extent of a crusted top layer.

"A different approach with Biostack will be required in this instance. The product has shown to work under these heavier burdens, but the timeframe is longer. The photoautotroph bacteria will work incredibly well when it is utilised in a functioning manure pond system."

Biostack comes in two formulations, BiostackSL for sludge breakdown and non lactating period pond maintenance and Biostack AP for ongoing pond maintenance.

Federated Farmers is celebrating following the Government's announcement that young farmers will be able to use their KiwiSaver funds to buy their first home or farm.

The Meat Industry Association of New Zealand (MIA) today announced that Chief Executive Officer Sirma Karapeeva has resigned from the role.

The winners of the 2026 Hawke’s Bay/Wairarapa Dairy Industry Awards were announced at the annual awards dinner held at Copthorne Solway Park in Masterton on Thursday evening.

Environment Southland is welcoming this week’s decision by the Environmental Protection Authority (EPA) to approve the release of Blaptea elguetai, a leaf‑feeding beetle that will help control the highly invasive Chilean flame creeper.

This March, the potato industry is proudly celebrating International Women’s Day on 8 March alongside the International Year of the Woman Farmer, recognising the vital role women play across every part of the sector — from paddocks and packhouses to research, leadership, and innovation.

Fruit trader Seeka posted a record profit and returns to shareholders in 2025.