Claas has updated its range of Orbis maize headers, adding the Orbis 450 which shares many features initially introduced on the larger Orbis 600SD and 750 units.

With a 4.5m working width, the unit incorporates the new tilting frame concept and redesigned T panels which help reduce weight and increase wear resistance.

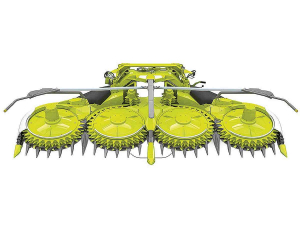

Newly designed fingers ahead of the knives ensure low-loss crop collection and have points which can be removed for harvesting laid maize. The new knives have a crescent-shaped blade which delivers top cutting quality in all crops.

The central crop feeding tower rotors have been repositioned to improve crop flow and angled forward to aid crop feed. They are also spaced wider, so increasing the feed channel to allow crop to be fed into the full width of the feed rollers and chopping cylinder. Augers at the edge of the Orbis help feed the crop into the header in poor conditions. These are driven hydraulically.

The new roller pendulum frame concept has lifted the crop flow to the centre of the Jaguar’s precompression rollers, improving crop even at full oscillation in uneven fields. The frame also handles the weight of the unit better and allows adjustment of the mounting angle, to regulate the header angle when the machine is travelling over softer ground.

The new frame also helps provide a shallower cutting angle, giving the benefit of a much shorter stubble height, allowing crops to be cut at less than 100mm stubble height if required.

Under the header, newly designed modular T-panels support the drive train and the discs.

The T-panels are press hardened and rounded, dimensionally stable, wear resistant and protect the transmission elements against wear and structural loads.

For road transport, the new Orbis 450 rapidly folds down to just 3.0m, offering an unhindered view, and an integrated communication module transmits data from the front attachment to the forage harvester. This saves Jaguar settings for subsequent use, even if removed then reattached.