The recently introduced Trimax Force mower/mulcher is a multi-functional machine that can leave a quality finish on grass or deal with prunings in vineyards and orchards.

Offered in working widths from 1.15 to 2.3 metres, the Force is designed to be operated with tractors from as little as 30hp right up to tractors of 90hp, which are typically found in horticultural situations.

Weighing in between 590 and 900kg, the units feature a heavy-duty construction, including 50% thicker endplates compared to the Warlord S3 machine from which the Force originates.

Offering a 0 to 60mm cutting height using heavy-duty flails. The cutting height is controlled with a heavy-duty skid and roller system that can be adjusted independently, with the latter using sealed bearing units to minimise service downtime.

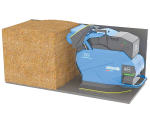

At the heart of the machine is a replaceable internal liner used to protect the main impact zones of the cutting chamber.

This move is said to offer around three times better durability than a more standard unprotected layout.

Also, in the area of the rotor, new rotor bearing assemblies have resulted in a 35% increase in static and a 50% increase in dynamic load capacities. Improved pruning guides funnel debris into the chopping rotor, resulting in a major reduction in post-mulching debris collection.

A reversible headstock with Cat1, Cat2 and Cat2n compatibility, allows the unit to be front or rear-mounted. Meanwhile, smoother exterior profiles greatly reduce the likelihood of getting snagged on vines or branches.

Available as centre-mounted, or with left or right-hand offset capability, there is also a hydraulic offset available on selected models. The manufacturer also points out that a reduced distance from the edge of the cutting rotor to the overall extremity means it is easier to get closer to plants.

Maintenance has been addressed by incorporating automated belt tensioning, easy access to grease nipples – without the need to remove guards – and the already mentioned sealed roller bearing units.

A range of options include heavy duty liners for the chopping rotor, roller scrapers to remove clippings during mowing, and mulching counter blades to produce ultra-fine mulch.

More options include pruning rakes to collect and move material into the cutting area, while the LED road lights and triangle help improve safety.

www.trimaxmowers.co.nz